Finishing

In-House Paint Capabilities

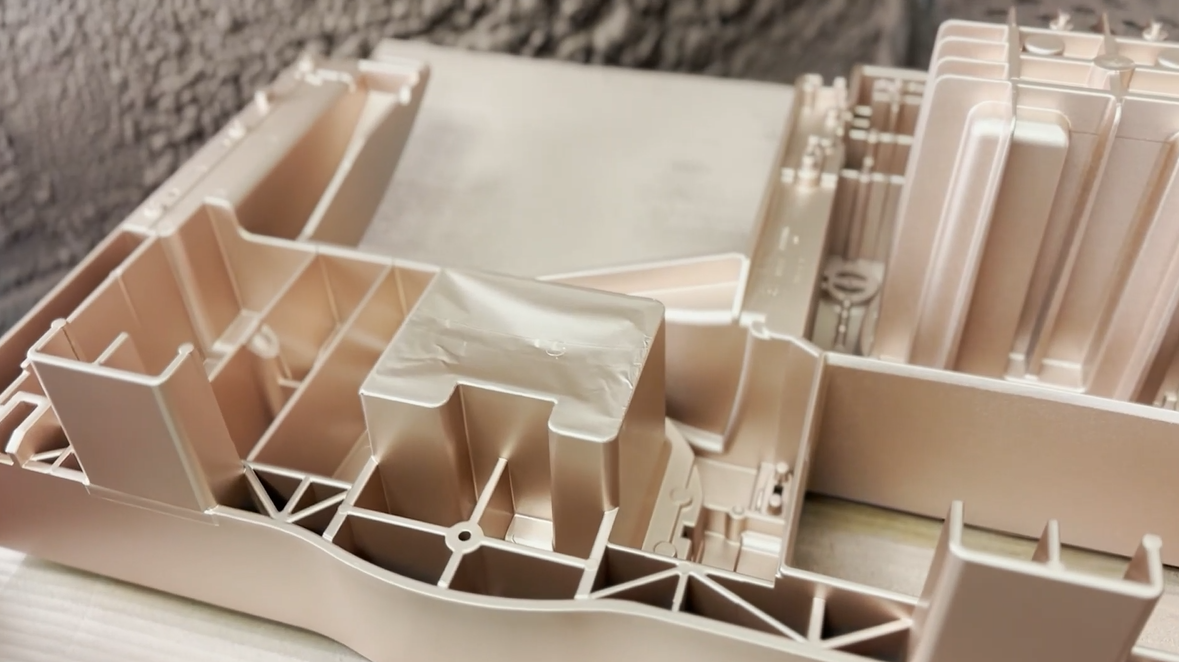

Once parts are molded, they take a quick trip down the hallway to our finishing team where the “wow factor” gets added. Our finishing department utilizes a continuous paint line system equipped with a computer-controlled paint management system, partnered with a 6,000 sq. ft. forced air-drying oven that is specifically designed for drying painted plastic parts.

We have multiple batch paint booths that handle complex parts that are multiple colors, have complex geometries, or have smooth coat finishes that may not be suitable for our large continuous paint line.

FM Corp is UL Certified to spray EMI Shielding on a handful of different substrates, and we have experience spraying on many others. Conductive spray-on material replaces large, expensive, heavy sheet metal doors/enclosures when EMI requirements are needed. With both part consolidation and reduced shipping weight, EMI shielding can present significant cost savings for our customers.

-

6,000 square foot curing oven

Computer controlled paint management system

Both paint & texture abilities

-

Two or More Colors

Smooth Coat Finishes

Complex Parts

-

Automated Process

UL Certified

Copper & Nickel Materials

Standard Finishing Process

-

Whether it’s just a rough passover with sandpaper to get your paint to stick better, or a full blemish repair, our sanding team will have your parts ready to paint in no time.

-

If sections of your parts can’t be painted, or if you have multiple colors, our masking team will ensure only the necessary sections are available to paint.

-

Our paint line can paint any color or texture to fit your product’s needs.

We are also certified to spray copper and nickel shielding to help with any EMI requirements that your parts may require.

-

If your parts require masking, they will also require unmasking.

-

We have a wide variety of logo applications including:

Silk Screening

Pad Printing

Hot Stamping

Inkjet Printing

Logo Applications

Silk Screen

Inkjet Print

Pad Print

Hot Stamp

Finishing Gallery